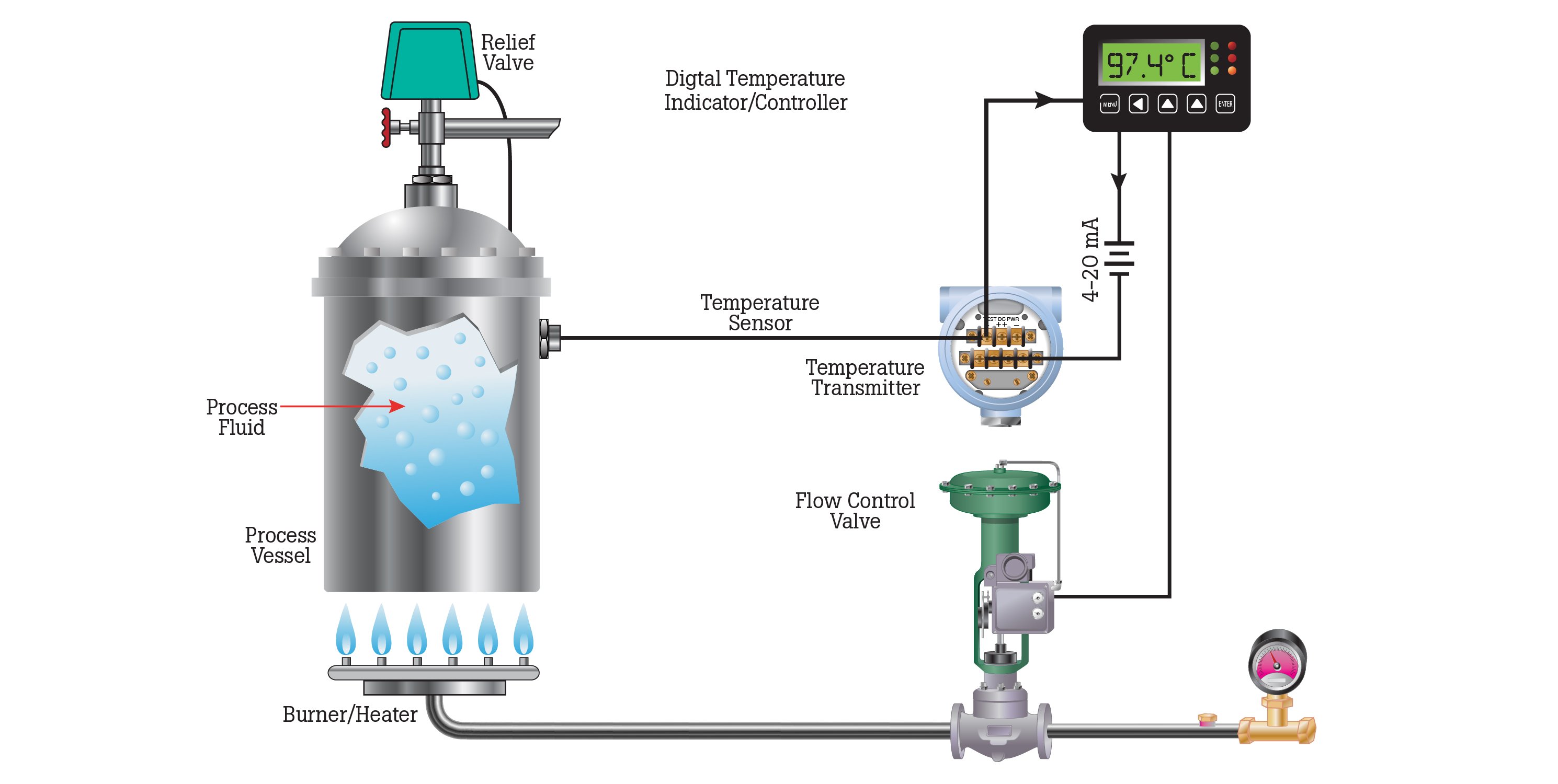

The 4-20 mA current loop has been the standard for signal transmission and electronic control in control systems since the 1950's.

In a current loop, the current signal is drawn from a dc power supply, flows through the transmitter, into the controller and then back to the power supply in a series circuit. The advantage is that the current value does not degrade over long distances, so the current signal remains constant through all components in the loop. As a result, the accuracy of the signal is not affected by a voltage drop in the interconnecting wiring.

Voltage drop

Voltage signals sent over a long distance will, however, degrade in accuracy and develop a voltage drop (using Ohm's Law) proportional to the length of the cable. Accuracy loss of the voltage signal would equal the mA signal value multiplied by the resistance of the wire.

The use of 4 mA as a "Live Zero" enhances the signal-to-noise-ratio at low levels. This Live Zero also makes a loop failure more apparent. A nonfunctioning current loop with an open termination or connection has zero current flow, which is outside the valid 4 to 20 mA signal range.

Verifying the 4 to 20 mA loop

Milliamp loop calibrators are typically used to test loops that measure pH, pressure, temperature, level and flow. Verifying the 4 to 20 mA loop is a crucial step in any instrument calibration. Full loop verification includes testing the output of the transmitter, the wiring, input to the control system as well as the control system input card and the return wiring back to the transmitter.