In every industry, technicians and engineers who work with automation, instrumentation, and control equipment and systems deal with measurement issues every day. Knowing that sensors convert characteristics of a physical environment or process is only part of the job; a lot can happen to these signals on the way to equipment or systems that require their input. Signal conditioning is how they’re getting measurable signals out of these sensors.

- What is signal conditioning?

- Types of signal conditioning

- Signal conditioning systems

- Mitigating noise for signal measurement

- Ground loops and noise

What is signal conditioning?

Technicians and engineers know that most industries are not necessarily signal-friendly. Ground loops and noise can threaten signal integrity. Some sensor signals are weak, some require conversion, and some can't produce signals without an external power source. Technicians and engineers who deal with measurement issues often use signal conditioning to obtain, maintain, and improve the quality of these measurements.

Signal conditioning is the preparation of an analog signal before it becomes digital. This manipulation of a signal prepares it so technicians and engineers can accurately and precisely measure it using digital tools.

Signal conditioning protects desired signals from unwanted components or effects by using isolation or filtration. Signal conditioning devices use isolation to minimize the effects of interference caused by ground loops or noise, which can affect measurement accuracy. Filters are designed to minimize noise by rejecting signals within a specific frequency range while allowing others to pass. For example, low pass filters built into many Fluke digital multimeters and clamp meters effectively block high frequency noise component, like VDFs, in measurement signals.

Signal accuracy vs signal precision

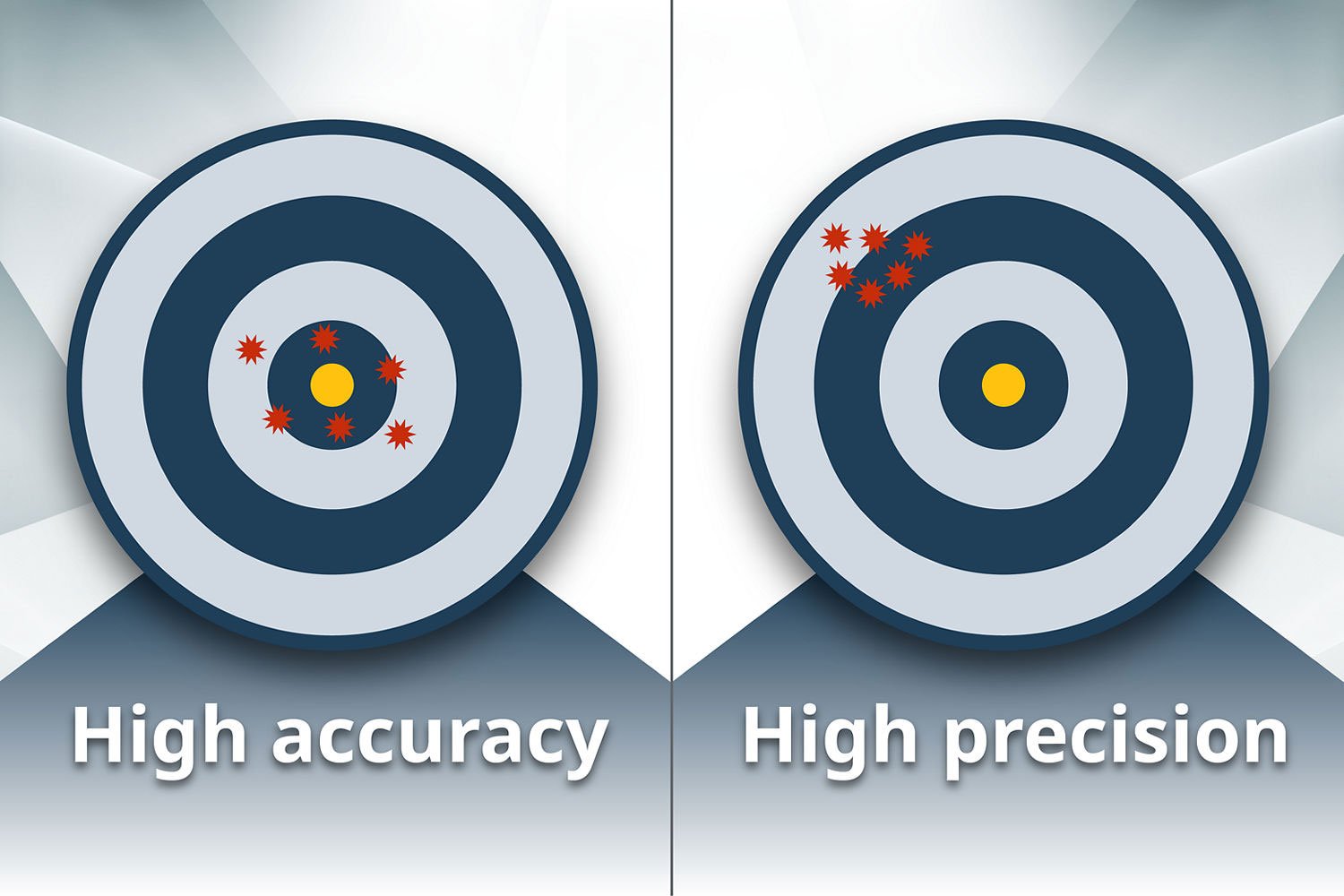

Accuracy and precision are often confused with one another, but they are not the same thing. Accurate results show how close the output is to the desired value. While precise results show how close measurements are to one another. If you’re looking at a bullseye, highly accurate results would look like a bunch of hits close to the center of the bullseye, as the center is the value you want to hit. Highly precise results could be anywhere on the bullseye, as long as the hits are clustered close to one another.

Taking the time to understand signal conditioning and take the necessary steps to convert when needed, can help ensure more accurate and precise measurement results.

Types of signal conditioning

Signal conditioning acts to translate the measurements from sensors to the devices that use their signals. Many measurement devices and their associated systems are picky when it comes to the types of signals they require. Therefore, the sensor signals must be translated, or converted, before measurement devices can use them. Depending on the starting and ending signal, a couple of different types of signal conditioning could be used.

Signal conversion

Signal conversion takes the output signal from one device and changes it into another signal for another. Types of signal conversion include amplification, attenuation, linearization, cold-junction compensation, and excitation. Some measurement devices prefer voltage, while others prefer current, it just depends on what you’re working with. Most of these devices require signals to have a much higher level than most sensors produce.

Thermocouples

Thermocouples remain the classic signal-conversion example, requiring three of the five signal conversion types: amplification, linearization, and cold-junction compensation.

Thermocouples are used in many applications but can be tricky to understand how they work and how to calibrate them. Fluke Calibration has a series of application notes to understand more about thermocouples:

- Thermocouple Fundamentals

- How to Select Thermocouple Calibration Equipment

- Calculating Uncertainties in a Thermocouple Calibration System

- How to Calibrate a Thermocouple

Amplification

Thermocouples produce voltages in the millivolt range. However, some of the temperature measurement devices with which they are used require a larger amount, either 1-5 V DC (Direct Current), 0-10 V DC, or 4-20 mA for proper operation. In these cases thermocouple signal must be amplified to be useful.

Linearization

Thermocouples are notoriously non-linear. However, other sensors such as resistance temperature detectors (RTDs), strain gauges, and accelerometers are non-linear as well. A sensor is said to be linear if the change in the value of the signal it produces is directly proportional to the change in value to the physical environment or process it measures. However, when sensors produce signals that do not relate linearly to their physical measurements, linearization must be used to make sense of them.

Cold-junction compensation

The connection between the thermocouple and the terminal of the measurement device also forms a junction, called the cold junction. If left as is, the cold junction will produce a measurement error. However, cold-junction compensation makes use of a thermally-sensitive device, such as a thermistor or diode, to simulate and apply the appropriate correction so the connection can be measured accurately and precisely.

Excitation

Some sensors do not produce voltage or current and consequently require excitation in the form of an external voltage, or current. Excitation is the process of adding external electrical input to generate a magnetic field. Some sensors that require excitation include RTDs, thermistors, strain gauges, and accelerometers.

Signal conditioning systems

When using signal conditioning in measurement systems, each sensor needs an individual signal conditioner based on the signal that sensor type produces. Signal conditioning modules and devices are available for most analog signal types, however, stocking spares for every type can become expensive and difficult to manage. Fortunately, there are also universal signal conditioners. Universal signal conditioners, or universal signal conditioning systems, accept a wide range of inputs and multiple outputs as well. These are an easier, most cost-effective solution.

Universal signal conditioners convert, isolate, and transmit signals from many types of sensors as well as controllers and other devices. These versatile signal conditioners typically accept current, voltage, thermocouple, RTDs, and resistance inputs. Typical universal signal conditioner outputs include current, voltage, and programmable relays.

Technicians and engineers who work with automation, instrumentation, and control equipment and systems apply signal conditioning to improve measurement accuracy and control system performance by optimizing signals from process sensors. However, these control systems must also be properly maintained and periodically calibrated. Fortunately, Fluke tools can help maintain the reliability, accuracy, and safety of process measurement and control systems.

Mitigating noise for measurement signals

Process indicators, data acquisition and collection equipment, PLCs (Programmable Logic Controllers), process control systems, and any other measurement device requires the appropriate signals - and nothing but the signals. In other words, these signals must be "clean" and noise-free. Motors, variable frequency drives (VFDs), welding equipment, and transients that occur due to starting and stopping equipment can produce noise that can affect signals traveling from sensors to their intended measurement devices.

Electrical and instrumentation wiring best practices - including proper grounding and shielding - go a long way to minimize unwanted noise. Using a portable oscilloscope you can monitor noise on control loops to get an idea of what you’re working with. Though it is also important to note that well designed and installed systems have fewer noise problems, many times this is not enough to get a clean measurement. Knowing when, where, and how to apply signal conditioning can help keep these signals happy and make measurements easier.

Ground loops and noise

Ground loops and noise can cause interference in measurement signals. A ground is supposed to be at ground potential and referenced to Earth. However, a ground loop exists when a single control signal has two or more grounds at different potentials and there is a conducting path between the grounds.

This difference in ground potential can create an unpredictable magnitude of additional current in the loop. This current is not part of the desired signal, and therefore distorts the signal and the measurement. Signal conditioning devices maintain signal integrity by breaking the ground loop current path.

Industrial equipment produces electrical noise that can affect measurement signals. Normal mode noise typically occurs in AC circuits between the neutral and "hot" wires. Common mode noise typically occurs between the neutral and ground wires but can also occur between the hot and ground wires.

While normal mode noise can also occur in DC measurement circuits, common mode noise is more regularly seen and causes the most measurement errors. In either case, isolating the signal can help prevent noise from affecting measurement accuracy.