By Ron Auvil

"My chiller plant is down, do you know how incredibly critical it is?"

In my role as a project manager and senior technician, I get calls like this every summer, usually at three in the afternoon on an especially hot day. The reason for this panic call is the sizable number of areas and processes in a modern building that require almost continuous chilled water flow.

One such application is the IT server room. If chilled water flow is interrupted for even a few minutes the IT server room might overheat and critical computer services could go down. Another vital area is a hospital operating room. In a plant, essential machinery uses chilled water for process cooling. While many plants have excess capacity, much of this capacity is not available at high ambient temperature and high humidity conditions.

Mechanical systems involved range from cooling tower fans to system pumps, compressors, and auxiliaries. Most problems can be broken down into mechanical, electrical, and control issues.

Cooling tower fans

Cooling tower fans "reject" heat from the condensing water to the atmosphere.

Tower fan mechanical problems typically include the fan drive system and blades. Vibration testing may be used to identify future problems. A thorough inspection during the off season should identify any tower fan mechanical problems.

Tower fan electrical problems might include the starter, wiring, or tower fan motors. Variable speed drives are commonly used. Components should be checked visually and with electrical diagnostic equipment.

Tower fan control problems. Most towers are controlled today with a building automation system (BAS). If the tower fans do not stage up properly, the programming at the BAS may be in error and need to be checked or changed.

System pumps

Chiller system pumps include the condenser and chilled water pumps. In many large, complex systems there are both primary and secondary chilled water pumps. Usually multiple pumps are available to vary capacity and to increase redundancy in case of failure.

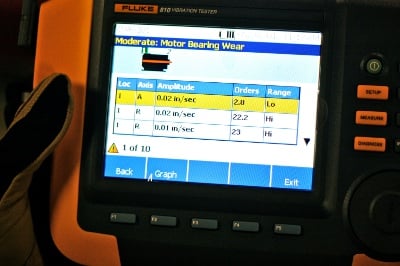

System pump mechanical problems may include vibration, alignment, and faulty seals. A vibration tester, such as the Fluke 810 Vibration Tester, can be used to diagnose common mechanical problems and help avoid pump failures in the middle of the season.

System pump electrical problems. As is the case with the tower fans, most pumps today are driven with variable frequency drives. One word of caution here: the drive has to be set up properly by the installing contractor. I was in a chiller plant recently in which none of the pump drives had been set up properly. This led to less than optimal performance. For more info on VFD problems read the Fluke application note "Solving problems after energy upgrades."

System pump controls. Again, these systems are usually controlled by a BAS. The failure mode of the BAS should be checked to ensure that a smooth transition from the "lead" pump to the "lag" pump will take place in case of lead pump failure. Every possible failure mode should be checked before the chiller plant is put into service.

Compressors

The compressor is the heart and soul of the chiller plant. While most of the chiller plants that I service utilize centrifugal chillers, screw, reciprocating, and scroll compressors are used as well. Any compressor failure will cause the system to go down and cause a backup machine to come on.

Compressor mechanical problems typically include the gears, drive, alignment, and bearings. Reciprocating compressors have pistons and crankshafts that are subject to failure. A wide range of diagnostics are available for the compressors, including vibration, oil, and refrigerant analysis.

Compressor electrical problems. Most compressors have complex electrical circuits that run the compressor and auxiliaries, and also provide capacity control of the compressor in order to match the load. The electrical circuits are subject to component failure. Fortunately, excellent modern diagnostic equipment is available. Checks typically include using an insulation tester to check the insulation resistance of the motors and all auxiliaries. Check current in each circuit, as well, to determine the condition of the motor.

Another electrical condition to monitor is the incoming power quality from the utility. A momentary problem with the incoming power supply can affect the whole chiller plant sequence.

Compressor control problems. Control sequences for a large chiller plant are complex. As mentioned before, the individual chillers, towers, and pumps are controlled in sequence to satisfy the load in the facility. The control sequences must be checked in exquisite detail. I have personally been in large chiller plants in the past months that have suffered a condition not anticipated by the control system. In these cases the unexpected condition caused the entire chiller plant to shut down. Catastrophe was averted but only barely, usually by putting the chiller plant devices in the "hand" position. A word to the wise—expect the unexpected. Examples include a power failure sequence, including a backup generator power failure sequence.

Auxiliaries

In many cases the chiller plant auxiliaries can be as important as the towers and compressors. Auxiliaries include oil pumps and heaters, chemical feed equipment, and purge systems. If a problem causes these systems to fail, the machines they serve go down as well. It is a good idea to ensure adequate service of the auxiliaries before startup, in addition to adequately servicing the major devices.

Continue the supply of vital chilled water

Any of the problems listed above can cause a chiller to go down. This may mean that the chilled water to critical areas is cut off, which in turn may cause a critical system failure.

Chilled water plants can be incredibly important to the continued operation of the facility. A small amount invested in the maintenance and diagnostics of the plant equipment can pay off in the continued supply of vital chilled water to your "incredibly critical" systems. And, perhaps, you will help me and my fellow professionals avoid those desperate phone calls!