Hundreds of thousands of new High-Voltage Direct Current (HVDC) power systems are being built across the country, from solar photovoltaic (PV) systems to electric vehicle charging stations (EVSEs). How do electricians stay safe while working on them? In this webinar for EC&M Magazine, sponsored by Fluke, senior power engineer and expert electrical safety trainer Tommy Northcutt discusses what every electrician should know about HVDC power system safety.

1. Why is HVDC technology growing? PVs and EVs

The North American electrical system is still predominantly powered by AC distribution, yet more and more of the devices we’re adopting and using (like computers, LEDs, solar cells, and electric vehicles) run on DC power. The two key technologies fueling today’s rapidly growing demand for new DC transmission systems are:

- Solar PV systems, including generation, battery storage, and inverting the power so that it can be used in AC applications.

- EVs and electric vehicle charging systems, including large DC power battery systems and chargers.

Now that HVDC systems are becoming more common, some electrical professionals are raising safety concerns about working with these “new” technologies.

2. What are the hazards of solar PV and battery systems?

As with any electrical system, the hazards are known and well understood: shock, arc fault, and arc flash. PV systems are complicated by the fact that the panel itself will continue to produce electrical energy whenever it’s exposed to light.

- Shock: The NFPA 70E standard defines 50 volts DC or greater as hazardous. The control measures are using insulating materials and maintaining distance boundaries. Specific to PV technology is the requirement for rapid shutdown systems in buildings, which protect first responders in emergencies.

- Arc fault: Fire is a potential hazard with any electrical system. The heat created by arc faults can deteriorate wire insulation, causing a spark or arc that can ignite a fire. PV systems are subject to both series arc faults caused by the disruption of continuity of a conductor, and parallel faults caused by unintentional current between two conductors, or between a conductor and ground (a ground fault). The control measure is installation of arc fault circuit interrupters (AFCIs) or ground fault circuit interrupters (GFCIs), plus use of additional protection components for high-voltage PV systems.

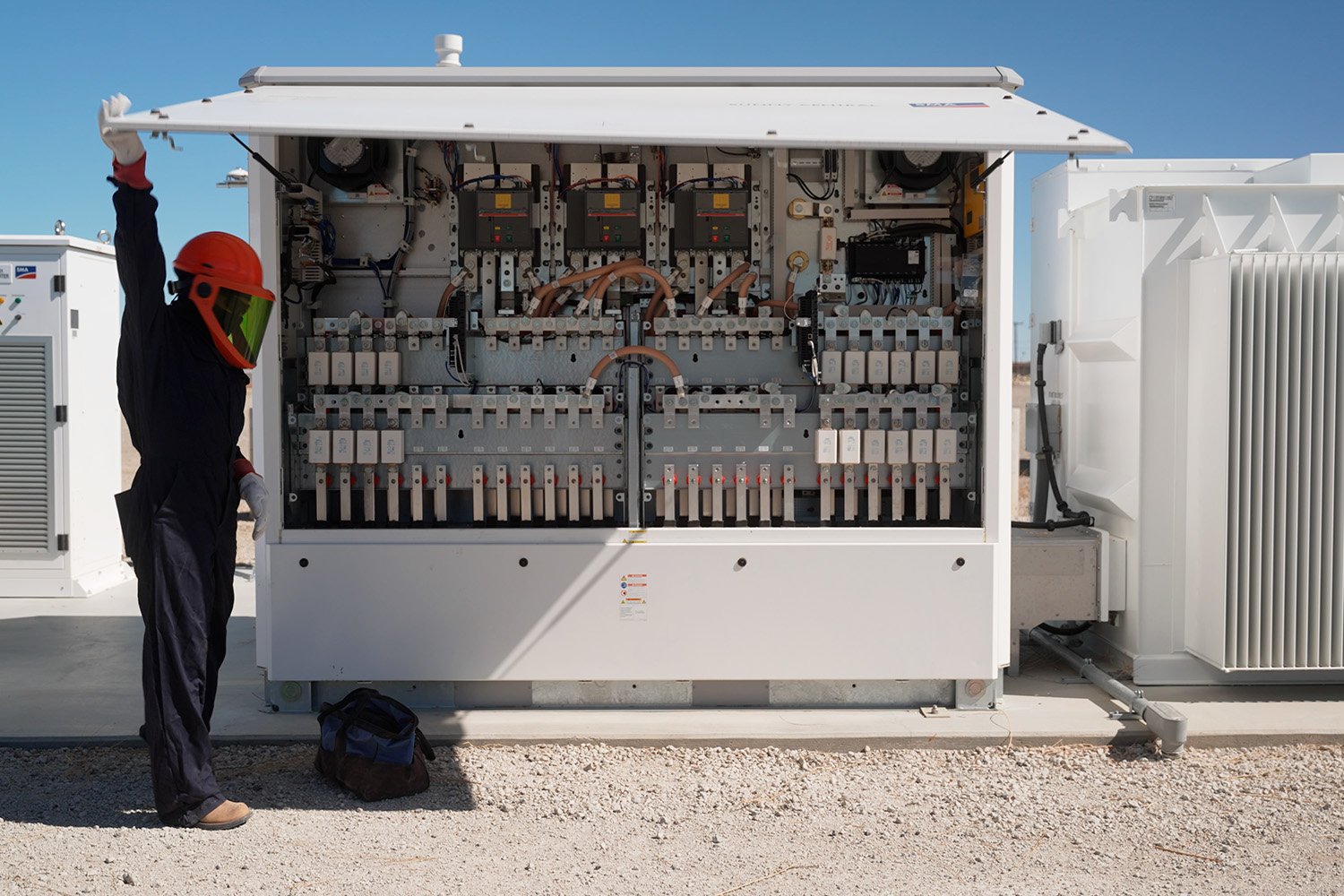

- Arc flash: Large-scale PV arrays with higher voltages are susceptible to arc flash, the dangerous release of hot gases and radiant energy at temperatures as high as 35,000 degrees Fahrenheit. It’s a particular danger for workers troubleshooting or performing maintenance in energized enclosures, and when checking medium- to high-voltage switchgear and transformers or other parts of the power distribution system. The NFPA 70E standard requires that an arc flash hazard risk analysis be conducted, and personal protective equipment (PPE) used, for DC systems over 100 volts; additional arc flash mitigation in PV systems is specific to the DC side (before the inverter) or the AC side (after the inverter). Control measures include designing systems to minimize the number of solar panels paralleled inside enclosures on the DC side, installing arc-resistant switchgear on the AC side, and using tools that are properly rated for the system.

- Battery hazards: Batteries come in many forms and sizes, from station-type batteries and solar battery banks to high-energy EV batteries. They all pose similar hazards: shock, fire risk, and thermal runaway (when a battery can no longer dissipate heat as fast as it’s generated), and with large battery systems, arc flash. They have similar control measures as well.

3. Do these new DC systems pose new hazards?

Although PV systems, battery storage systems, and EVSE systems pose some unique safety risks, are they truly new hazards — or just new applications of the hazards you already know? The advice here is to pause. Think through the task to be performed. Then boil the hazards down to the basics: shock hazard and arc flash hazard.

The shock hazard is fully and effectively covered by NFPA 70E. While research is still being done on DC arc flash analysis, currently the best approach is to remain outside the arc flash boundary whenever possible and use NFPA 70E Annex D to help calculate some conservative energy values to determine the appropriate PPE.

The best protection is to educate yourself and your team on the hazards and hazard-mitigating techniques for the DC systems you’re working on. Understand what the hazard is, evaluate the specific scenarios and variables that impact your exposure, and think through how you’ll protect yourself and your team. Although some of these systems seem new, different, and complex, you’re facing the same basic hazards of the electrical profession: voltage and current. You can apply the same principles you've always applied from NFPA 70E to stay safe.

Download the webinar transcript

About the experts

Tommy Northcutt, PE, CRL, CMRP, is a senior power engineer and branch manager for Jacobs Technology, Inc. With more than 20 years in the electrical industry as an electrical engineer, project manager, arc flash program manager, electrical safety trainer, and utility manager, he brings a broad range of experience into his passion toward electrical safety. As a certified reliability leader, and a certified maintenance and reliability professional, he also has a clear vision of how maintenance of electrical equipment has a direct impact on personnel safety. Tommy has a B.S. in electrical engineering and is a licensed professional engineer in two states. He is also a principal committee member on the NFPA 70B committee for recommended practice for electrical equipment maintenance.

Joining in at the end of the presentation is Sean Silvey, Fluke application specialist, to discuss some of the best Fluke tools for PV, battery system, and EV charging station applications.