By Randy Barnett

If the only power quality problems were created by single-phase nonlinear loads such as copy machines and printers, we might think the world of power quality measurement was a lot simpler. However, in the world we live in today, whether you're conducting power quality surveys or troubleshooting electrical system issues, you need a three-phase power quality analyzer. Setting up a power quality analyzer with five voltage leads and four amp clamps, and then selecting from various screens that that offer well over a dozen different parameters to measure and record, can all be intimidating. However, three-phase power quality analyzers such as the Fluke 435, as powerful as they are, are simple to use once you understand the basics of operation.

Monitoring three-phase power quality is a must. Whether you troubleshoot mysterious electrical problems or provide additional services to a client, it is three-phase power that is provided to commercial and industrial customers and three-phase power that is distributed throughout a facility.

Installing a three-phase analyzer

Unless you're troubleshooting a specific problem, a good place to start with a general power quality survey is the point of common coupling (PCC). The PCC is the point at which the electric utility and the customer interface occurs. For practical purposes, the PCC is the customer side of the utility revenue meter. Power quality analyzers should be used at a safe location downstream of the main disconnect and installed following all safe work practices.

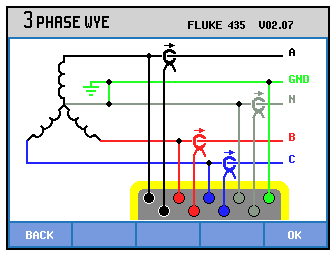

Before installing the three-phase analyzer, select the distribution system configuration on the instrument "setup" screen. The Fluke 435 offers ten different configurations. The three-phase Wye is most commonly used in commercial and industrial applications with voltages of 480Y/277 or 208Y/120. To avoid confusion when connecting leads, use the colored lead markers to match voltage and clamp leads to the color depicted on the analyzer configuration screen.

Always connect the ground lead first for safety, then the remaining voltage and current leads. Press "Scope" to check for proper connections and look for the proper rotation, verifying all leads are connected properly.

Measuring and analyzing data

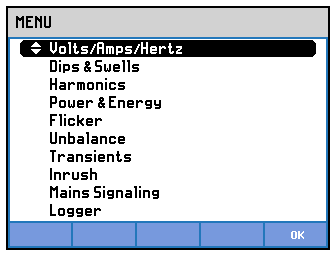

Begin measuring and analyzing data by pressing Menu to select and set up the desired parameters to be analyzed. The Volts/Amps/Hertz screen is good place to start and to get the overall picture of system conditions. An important value is the Crest Factor (CF) indicated. CF is the ratio of peak voltage to RMS voltage. The amount the CF drops below 1.4 indicates the extent of flattening of the sine wave peaks. Sine waves that tend to flatten out do not allow the capacitors in power supplies to charge to their maximum value (these capacitors are designed to charge to the peak voltage). Capacitors not fully charged could result in problems, from computer lockups to spurious alarms on electronic equipment. Conversely, if the CF rises above 1.4 this indicates another type of distortion, and if peak voltage rises too high, it can cause component break down. It is important to note that an RMS multimeter would continue to read satisfactory values, while the CF has deviated away from the nominal 1.4 of the pure voltage sine wave to cause equipment problems. For this and other similar reasons, DMMs cannot be used to troubleshoot power quality problems.

Selecting Dips and Swells on the Fluke 435 menu will allow the user to view and record voltage variations over time. Sags (referred to as "dips" in the European standards) and swells are fairly common power disturbances. Sags and swells are short-duration voltage variations either down (sag) or up (swell) in the distribution system. Sags can result in improper operation of electronic equipment, motors tripping off the line, and even cause relays to chatter or drop out. Over a period of time swells can damage insulation and cause failure of electronic components.

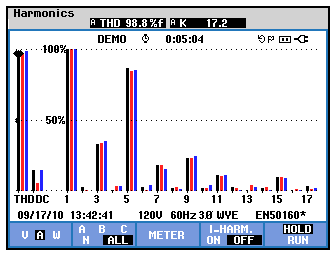

Nonlinear loads, such as variable frequency drives (VFDs) and uninterruptible power supply (UPS) systems produce harmonic voltages and currents. Harmonic currents are integer multiple frequencies of the fundamental frequency (60 Hz). For example, the third harmonic is voltage and current that flows at 3 x 60 Hz, or 180 Hz. The fifth harmonic would be current at 300 Hz. Harmonic currents distort the fundamental (60 Hz) sine wave, causing improper operation of electronic equipment. The total harmonic distortion (THD) is the sum of the distortions created by harmonics and represents the magnitude of the total distortion. At 5 percent voltage THD the operation of loads may be affected. THD can be easily read on the power quality analyzer.

The prevalence of certain harmonic frequencies may cause the overheating of neutral conductors, reverse torque and overheating in motors. The normal cycling of nonlinear loads will vary the frequency and magnitude of harmonic currents in the distribution system. By selecting the Harmonics function from the menu screen, you can view the harmonic frequencies and amplitudes present.

As utility costs increase, power and energy usage in facilities is of more and more concern. Power factor penalties can be significant - ranging into the tens of thousands of dollars per month for even a mid-size manufacturing facility. Power factor is a ratio of the true power being consumed in a facility (kW) to the apparent power (kVA) delivered by the utility. If too much apparent power is being delivered compared to the amount being used to do work, utility power factor penalties can result. By selecting Power and Energy from the menu screen, you can readily read power factor. Large motor loads causing power factor problems can be isolated and power factor correction capacitors installed - often totally eliminating power factor penalty charges.

Commercial and industrial customers may also pay peak demand charges. Peak demand is the maximum amount of kW used over a fifteen- or thirty-minute period. Utilities size their equipment to meet this demand and typically charge for kW usage based on peak demand values. With the power quality analyzer, kW, kVA and kVAR (reactive load) can all be monitored and, then, intelligent energy management decisions made.

Flicker is a perceived, unsteady wavering of light output due to voltage variations. Flicker is measured as both short term and long term values. Too much flicker means human discomfort and possible utility penalty charges. Selecting the Flicker screen from the menu while troubleshooting power quality problems can help isolate the cause of flicker such as, welders, arc-furnaces or cycloconverter generators.

Unbalanced voltages in a three-phase system occur when there is unequal loading between the three phases. Placing too many single-phase loads on one particular phase will result in a lower voltage on that phase as compared to the other two. Voltages to three phase motors will now be unbalanced. Variable frequency drives may produce increased harmonics and drive output can be affected. Voltage Unbalance is measured using the Unbalance screen and should not exceed 2 percent without corrective action taken.

Transients are very short duration changes in voltage typically occurring for only a fraction of a sine wave, but can create undesired effects. While a lightning strike may be considered the most severe transient, other causes such as the operation of large loads or capacitor banks also create problems. Failure of electronic equipment is one of the gravest issues caused by transients. Because of their very nature transients can only be captured and measured with specialized monitoring equipment. The Fluke 435 Transients function records voltage levels thus monitoring for transient conditions.

Inrush currents for motors when they are started may run from five to seven times (or more) of their normal full load current ratings. These large currents can cause significant voltage sags in the distribution system creating the problems mentioned earlier inherent with these sags. With the Inrush function of the Fluke 435 inrush current values can be measured over time as motors cycle on and off.

Utilities may use their power distribution system to carry higher frequency signals to switch appliances on and off (ripple control). Selecting Mains Signaling from the menu allows the Fluke 435 to capture when these signals occur, to aid in troubleshooting suspected signaling problems.

Selecting the Logger function from the Fluke 435 menu allows logging of several system parameters including voltage, amperage, energy and crest factor variances caused by harmonic distortion. The ability to download data collected over time and then to be able to compare that information to operation of plant equipment, such as large motors and nonlinear loads, can help in troubleshooting and identifying the source of power quality issues.

Reducing energy costs

Power quality analyzers such as the Fluke 435 are powerful measuring and recording tools that can not only diagnose and isolate unique electrical distribution system problems, but can help reduce energy costs as well. Payback times for the investment in such equipment and associated training can be infinitesimally small when downtime or equipment damage is considered. The key is finding a power quality analyzer that measures and records needed data, is easy to set up and use, and then provides for downloading and analysis of that data. For those already performing power quality surveys, or those anxious to learn the fundamentals of power quality - what to measure, what to look for and how - the Fluke 435 fits the bill.