The digital multimeter is the mainstay of electrical troubleshooting and the tool that most of us reach for first. In Beyond the Multimeter, we look at five examples of how reaching for an oscilloscope next can make troubleshooting faster, easier, and more effective.

Part 5 describes using a digital multimeter and an oscilloscope to troubleshoot a power supply (see Figure 1) with an intermittent failure.

The dc power supply unit (PSU) is one of the most critical components in any automation or process system. If a PSU has a "hard failure," you simply replace it and move on. But what if the problem is intermittent? Or what if the problem returns a short time after you replace the PSU?

Without the right tool, finding the root cause of the problem can be a long and tedious process.

In this example, the "Error" LED on a dc power supply has turned on. Your troubleshooting task is to determine if the problem is the power supply, the input supply voltage, or a load change on the demand side.

Troubleshooting with a digital multimeter

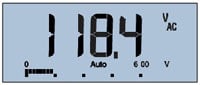

Using a digital multimeter, you measure the line input voltage and see that it looks OK (see Figure 2).

Next, you check the dc output voltage, and again everything looks good (see Figure 3.)

You decide to swap out the PSU with a known good replacement unit and hope for the best. However, when you come back two hours later, you see that the fault indicator LED is on again. What should you do now? This is where an oscilloscope can prove its worth.

Troubleshooting with an oscilloscope

Check the PSU's input and output

First, you connect the oscilloscope to the power supply's ac line input terminals and check the input waveform visually for any fluctuation, distortion, or dropouts. You see that the ac line voltage is a perfect sine wave (see Figure 4).

Having established that the ac supply voltage is good, you next check the dc output voltage and see that that it looks good as well.

Note: Some oscilloscopes may require a separation transformer or a differential probe to measure the line input voltage and the dc output voltage simultaneously.

Check the PSU's input and output over time

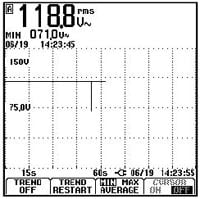

Because no problems are immediately obvious, you next track the power supply's input and output over time using TrendPlot™ on a Fluke ScopeMeter® test tool. If there's a disturbance, TrendPlot™ captures and plots it just like a paper chart recorder, telling you the time and magnitude of the problem.

Using TrendPlot, you determine that the line input voltage dropped to 71 volts after 14 hours, 23 minutes, and 15 seconds, causing the "Error" LED to turn on (see Figure 5). The fault is in the ac supply, not the PSU.

Another scenario…

What if the TrendPlot reveals instead that the ac line voltage input is OK over a significant period of time? The next step is to use TrendPlot to check the PSU's dc output voltage.

To measure the PSU dc output current and voltage with TrendPlot:

- Place a current clamp around one of the dc supply conductors (see Figure 6) and connect the clamp to channel A of the ScopeMeter test tool.

- Connect channel B to the power supply's dc output voltage.

- Start TrendPlot.

Now you can plot both the PSU's output current and voltage over time.

TrendPlot reveals that at 16 hours, 33 minutes, and 59 seconds, the load current exceed the maximum rating of the power supply, causing it to drop out (see Figure 7). Time to look "downstream" of the supply for what's drawing too much current, or it's time for a bigger power supply!

The bottom line

A digital multimeter can give you precise, real-time measurements, but the Fluke ScopeMeter enables you to see the actual voltage and current waveforms.

TrendPlot works like a paperless chart recorder to capture disturbances, fluctuations, and other anomalies for up to sixteen days, unattended.

The more you can see, the more you can fix!

- Beyond the Multimeter, Part 1: Troubleshooting a Variable Frequency Drive with a Multimeter and an Oscilloscope

- Beyond the Multimeter, Part 2: Using a Multimeter and an Oscilloscope to Troubleshoot Transient Voltages in Variable Frequency Drive Output

- Beyond the Multimeter, Part 3: Troubleshooting a Rotary Encoder with a Multimeter and an Oscilloscope

- Beyond the Multimeter, Part 4: Troubleshooting a Proximity Switch with a Multimeter and an Oscilloscope