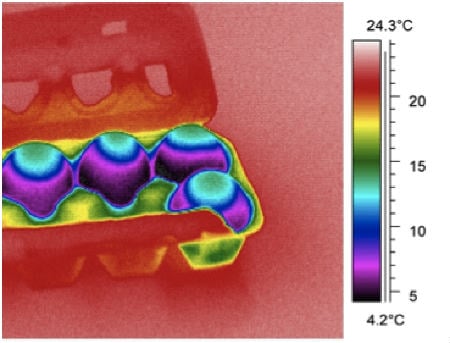

Thermographers are often surprised by what they find because they look at the world in a much different way than the average person. A case in point comes from John Snell of The Snell Group who discovered a new technique for tank level measurement. When he was just learning to use a thermal camera he started poking around in the kitchen looking for targets—he decided to scan a carton of eggs and was quite surprised by what he saw which gave him the idea to use the thermal camera as a tank level indicator or gauge.

The liquid/air interface of an egg is usually obvious. The liquid (at the bottom) can be distinguished by the lower temperature just like the liquid level in a tank.

The liquid/air interface of an egg is usually obvious. The liquid (at the bottom) can be distinguished by the lower temperature just like the liquid level in a tank.“The cause of the remarkable thermal pattern seemed obvious but only after some further testing was I willing to say it was due to the liquid/gas interface formed by the membrane inside the egg,” said Snell. “For the level to be revealed, the egg had to go through a temperature change—in either direction—and the air, with its lower thermal capacitance, always changed more quickly than the liquid. The idea to use a thermal camera for tank level measurement was not obvious at first—it simply seemed like something cool.”

Practical application of thermal imaging to tank level measurement and inspections

Snell realized that the colorful thermal pattern occurred because each egg was basically a small tank nearly full of liquid—like the many tanks found in the industrial facilities where he often taught. As he scanned real industrial tanks with a thermal camera, he found that, from a thermal perspective, they behaved in a similar fashion to that first carton of eggs. He also learned that it was quite easy to locate the liquid levels—even in huge tanks if conditions were good, because outdoor tanks had predictable heating patterns.

For tank level measurement, inspection, or verification, use a thermal camera – a new type of liquid level measurement device

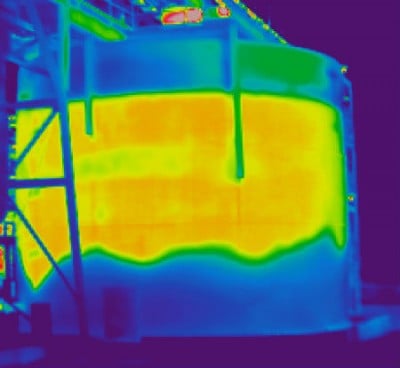

For tank level measurement, inspection, or verification, use a thermal camera – a new type of liquid level measurement device  Sludge, liquid and gas are all visible in this thermal image of a large industrial tank. Exactly what the levels of each will look like relative to each other depends on where the material is in its temperature transition.

Sludge, liquid and gas are all visible in this thermal image of a large industrial tank. Exactly what the levels of each will look like relative to each other depends on where the material is in its temperature transition.- Large tanks were warm on top by mid-day and cooler by early evening.

- Liquid inside the tanks, with their greater thermal capacitance, stayed nearly the same temperature night and day.

- Sludge levels were often apparent as well, typically showing an irregular shape. Exactly when they would distinguish themselves from the liquid depended on certain conditions and the type/density of the sludge.

- “Floaters” like waxes or foams can often be seen with the right conditions and a temperature swing.

- Content levels in silos and insulated tanks could also be identified even if their exact thermal characteristics may be a bit different than liquids.

How to measure or inspect tank levels with a thermal camera

To see this process for yourself, Snell suggests finding a tank located in the sun and scanning the side over a few hours. If you can’t see any temperature difference with the thermal camera, it could mean the tank is completely full or empty; or it could be the point where there is little temperature difference between the liquid and the gas.

You can either wait for a change in temperature or you can force that change to happen by simply spraying the side of the tank with water and waiting for evaporative cooling to work its magic.

Determining the liquid levels of eggs is just a fun way to learn thermography. However, it points to an important application for thermal imaging, which is locating, measuring or verifying the content level in large tanks or siloes. Most of these containers have level indicators, but process operators and industrial engineers still like to validate their readings with a second methodology. Thermography has proven to be a very easy and practical way to do that.