There are a number of areas where moisture can accumulate that are often overlooked in typical inspection processes or require extensive damage to the property to find them. That is why many are turning to thermal imaging as part of their building inspection regimen.

According to the U.S. Environmental Protection Agency, there is no practical way to eliminate mold spores in an indoor environment. The best way to control mold growth is to control moisture, which you can use thermal imagers to detect. Finding leaks or water damage before mold has a chance to grow and spread ccan save time and money.

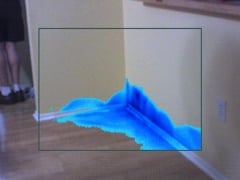

With thermal images, insurance carriers can better detect water damage, reducing unforeseen conditions and later requests for more abatement. A thermal imager can show the presence of water below a surface because of properties such as heat capacitance which is the normal method of choice when looking for failures in flat or low slope roofs. The Evaporative Cooling effect is usually the most powerful indicator when moisture gets into studs, insulation, and other interior wall components.

In the past, infrared technology has successfully been used to detect roof failures as well as in the fire and water restoration industry. With the technology available today, building industry contractors can combine thermal imaging with their building inspection skills to make more meaningful and accurate assessments and have the added benefit of expanding their business.

Thermal imaging in building inspections

Forensic investigation is the process of discovering building failures – whether it is for a homeowner complaining about a roof leak, a business that just had a flood, or collecting data for a lawsuit. Typical areas where defects can be found include:

- Low, sloped roofs

- Electrical problems

- Plumbing or HVAC failures

- Insulation failures

- Water intrusion from any number of failing exterior components

There are many components of a building inspection and forensic investigation relating to building failure or moisture problems that could use a combination of traditional inspection techniques and infrared cameras. While infrared cameras may not be able to answer all your questions, it can save considerable time and expense for the building owner and help to pinpoint problems more quickly and more accurately.

Traditional water and mold tracking methods

If a building owner notices water on the carpet near a window, traditional investigative methods might include "tracking" with either an invasive or non-invasive moisture meter. This method would try to determine if the water is coming through the wall, from the window, or running down the wall cavity from some other entry point. Eventually this would require some means of invasive investigation like cutting open drywall to try and find the leak, opening exterior envelopes to look at flashing detail, and then adding water in order to duplicate the behavior.

With an infrared camera, such as the Fluke PTi120 Pocket Thermal Camera, you can quickly and non-invasively zero in on the probable area to easily identify the anomalies created by evaporative moisture cooling. In the carpet example above, if the water was coming from the roofline or some other ceiling transition area, you would see the anomaly either in multiple locations or as a continuous anomaly from ceiling to floor. Ultimately the investigation may still require invasive action, but the infrared camera gets to the leak or mold location much quicker and with less intrusion to the building envelope.

How to conduct a moisture detection investigation

Before starting an investigation

Often an infrared inspection request comes in after the fact, so you aren't able to see the problem at its optimal condition. When that happens, it may be necessary to reintroduce water to the probable affected area. Before you start, be prepared to ask and answer a few questions that your customer may have. The history you learn about the building will direct you to the area for starting the water test.

You should ask the following questions about the building:

- How old is the building? (This gives an idea of the type of failure.)

- When did you first notice a problem and was it during a rainstorm?

- Was it a hard rain?

- Do you only notice the problem after many days of rain?

- If it is an exterior wall, and rain is not involved, is the landscaping running against the same wall? Is there exterior staining from sprinklers?

- Is this a multiple-story unit? Is it directly below a bathroom or kitchen?

- What kind of access is around the affected area? (i.e., is this a 3-to-4 story building?)

- Does it have extensive landscaping?

- Have you conducted any repairs recently? (e.g., reroofing, painting, HVAC).

Some of the most commonly asked questions of investigators include:

- What if the leak dries before you are scheduled?

- Can you only conduct IR camera investigations after it rains?

- Can it see through anything (e.g., concrete, stucco, siding)?

- How long does it take?

- How much does it cost?

Beginning the investigation and water test

The next step is to prepare the interior to minimize any further damage and document the affected area in its existing "before test" condition using digital and thermal photographs accompanied by a brief description. Setting up your before test scans with a thermal camera like the Fluke TiS120+ Thermal Imaging Camera is a simplified process. Because the camera can not only take thermal images, but can take photos and voice notes to accompany them, so all of the information you need before, during, and after your test can be organized and stored together.

To reintroduce water to an affected area, always start at the bottom and work your way up, unless evidence from the preliminary investigation shows moisture coming from above (e.g., the roof and ceiling are the affected areas).

Always document the start and stop times and move the water to each new location in eight-to-ten-minute increments. You should not have to exceed 30 to 45 minutes of water testing on one specific area.

Once you have duplicated the leak, stop testing in that location. However, continue up the exterior wall to confirm there are not multiple locations. Take notes or voice record the steps you are taking and a brief description of every thermal photo. This is important since digital photographs may be easily identifiable, thermal photos may not make sense later without the notes. You can use IR PhotoNotes® on Fluke’s thermal cameras to store photo and voice notes with the thermal images.

Weather watching for success

It is also important to pick the optimum time for testing and to maintain proper temperature control. Keep in mind that the greater the span in temperature from outside to inside the building envelope, the better the thermal results. To ensure a successful thermal test, adjust your investigation to accommodate the weather conditions. For example, if the weather is very cold outside, manipulate the temperatures of the building's interior temperature and turn up the heat.

A warm/hot climate is excellent for thermal investigations, since air conditioning is cooling the building interior. The water used in testing also tends to be cooler, creating greater variance in temperature and therefore generating better thermal images.

Keep an eye on the type of materials as well. Exteriors such as stucco are more porous, absorbing and retaining moisture, providing better exterior shots than siding, which hides water behind the thick planks. You can also use hot water on a cold exterior, but it is more difficult to apply enough to locate the problem.

Count on building industry experience

Even when you pinpoint areas of concern, it doesn't hurt to talk to the experts. Anomalies in building envelopes may appear fairly easily, but if you don't have construction experience, consider teaming up with a construction expert to help interpret the results. Save your comments for the report, since any spoken comments can easily be misinterpreted by the layperson or homeowner, resulting in problems later.