A voltage and continuity tester is the electrician’s primary safety tool—the first line of defense in an inherently dangerous and often confusing environment. The most common application of a voltage tester is at the breaker box or circuit panel. Because this is typically at the point of entry of the main electrical feed into a building, this is where risk of encountering high energy in the form of an electrical impulse (transient or spike) is greatest. Given these circumstances, the question “how safe is this voltage tester?” is critically important for electricians and their employers. The first step in answering this question is to evaluate the device’s overvoltage category rating and to confirm that an independent testing lab such as UL, VDE, TUV or CSA certified the rating.

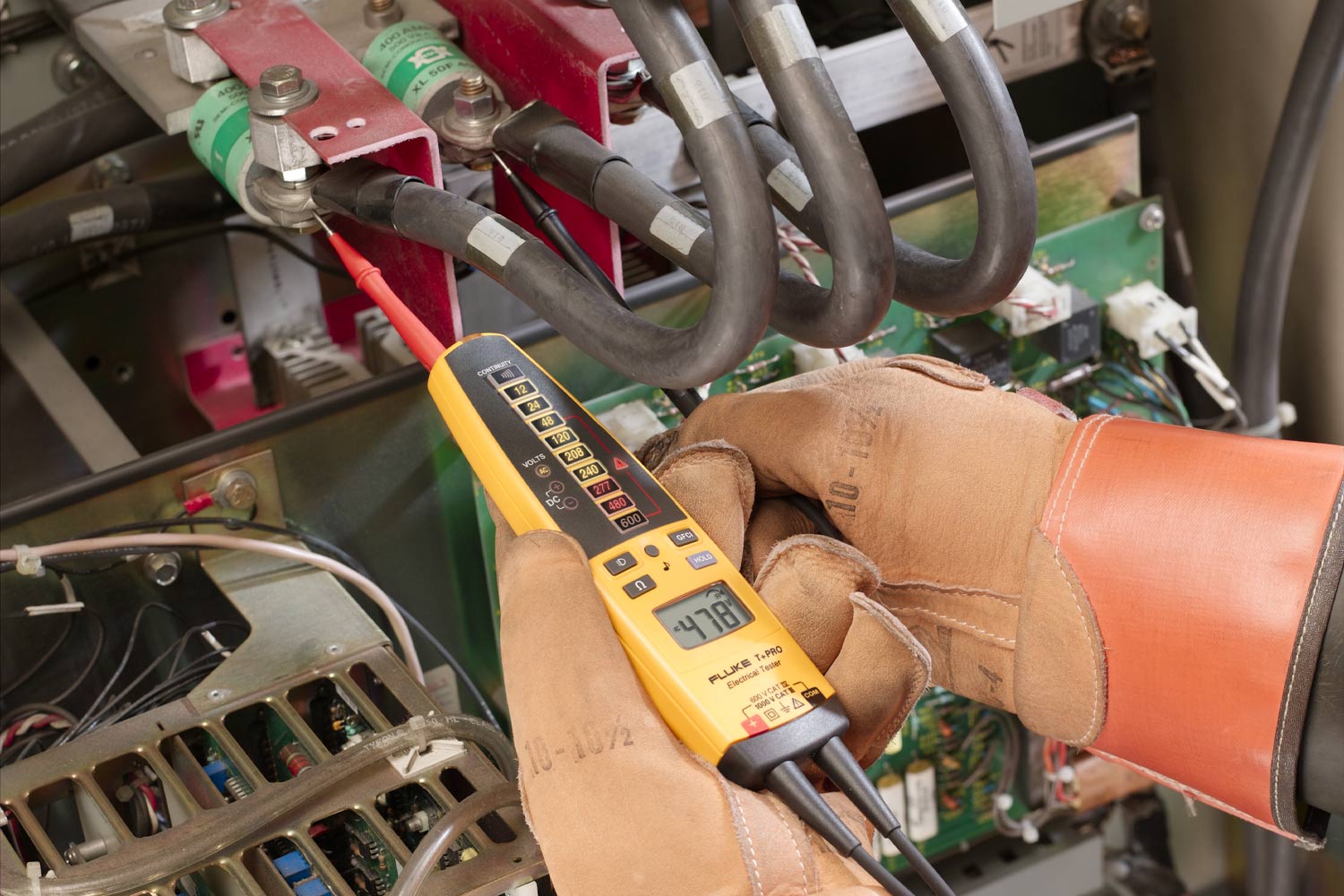

T+ PRO indicates voltage through light, sound, and vibration. Tester can also detect live voltage even when the batteries are dead for added user protection and convenience.

Regardless of whether a voltage tester is evaluated by an independent third-party test laboratory in North America such as CSA, UL, or a European test laboratory such as VDE in Germany, they all use the same threshold levels for impulse protection from the IEC61010 standard. For any impulse of electrical energy at or below the critical threshold established by the standards listed above, the tester must be able to absorb the energy without causing personal injury to the user. For example, a CAT III 1000 V rated device must be capable of withstanding an 8,000 V impulse without endangering the user.

Solenoid tester vs electronic digital tester

So how does all of this relate to the safety of common voltage testers? The best place to look is at the fundamental design difference between a solenoid tester and an electronic tester. A solenoid is an electromagnet made up of many windings of very thin enamel-covered wire. Solenoid testers are recognizable by their mechanical pointer displays, and clacking noise heard when the user applies a voltage. Some also produce a humming sound and vibration. Typical electronic testers, on the other hand, use electronic circuitry and components designed to indicate different levels of voltage through visual, audible, or vibrotactile feedback.

How safe are solenoid testers?

When hit with an impulse, many solenoid testers are at a disadvantage because of their basic construction. These solenoid testers rely on the very thin coating of insulation on the thin copper wire wound around a bobbin not breaking down when the impulse comes in through the test leads. A solenoid in isolation is not designed to be an impulse-suppression device, so it is very hard to predict if and how this breakdown will occur from one solenoid to the next.

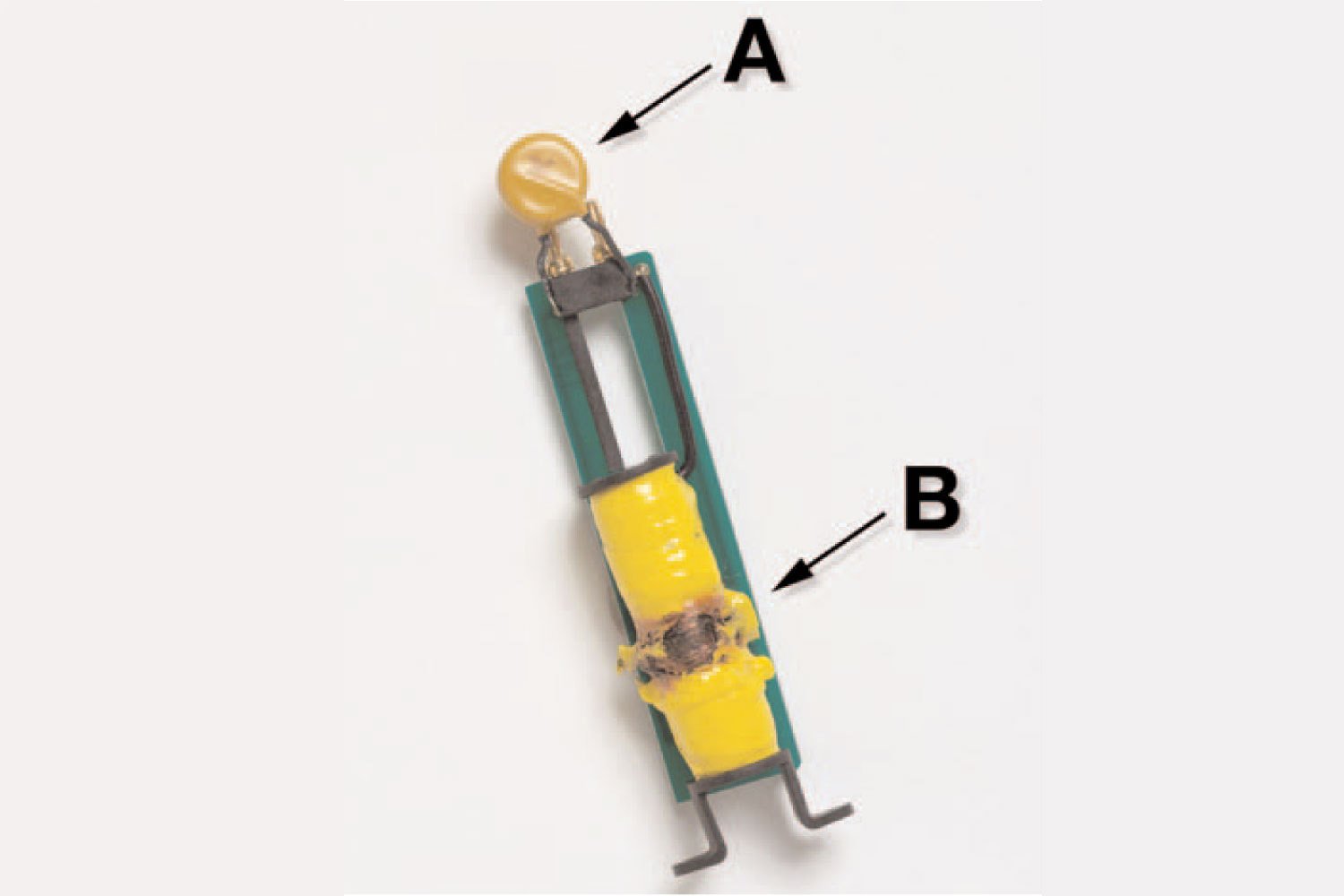

Solenoid tester users must be very careful to observe the duty-cycle limitations. If a solenoid tester is left connected to a voltage source, it will overheat and can self-destruct by exploding on the users’ hand. Input protection devices won’t prevent this (Figure 1).

Figure 1: This solenoid tester experienced a catastrophe failure after receiving an impulse. Even with an MOV (metal oxide varistor) (see A), the unit will still self-destruct from overheating (see B).

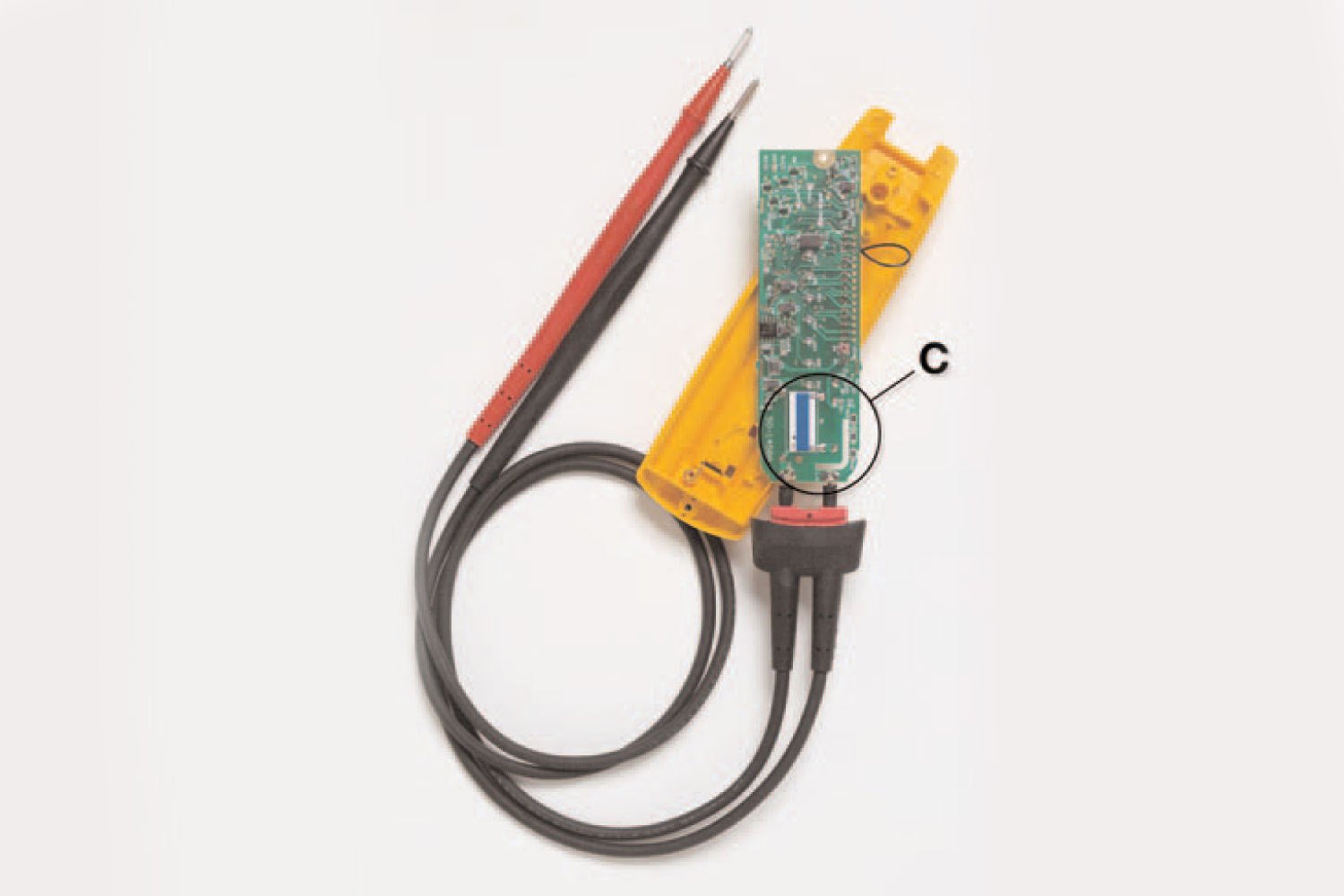

Figure 2: Current-limiting resistors (see C) protect this electronic tester which results in a predictable failure mechanism when the tester is exposed to electrical impulses.

In a typical electronic tester, an engineer designs a protection circuit using current-limiting resistors and spark gaps, resulting in predictable, repeatable, safe and controlled response to high-energy impulses (Figure 2). An overvoltage category-rated voltage tester must protect the user from a specified level of impulses but does not have to protect the tester from damage. However, the Fluke design philosophy of dependable and safe goes beyond the requirements of the overvoltage standards and the testing laboratories. Fluke builds into each tester the capacity to continue to function reliably after encountering multiple impulses at or below the level defined by the standard.

To summarize, solenoid tester designs are based on a component that was not intended to be an impulse protection device, so they are inherently at a disadvantage when it comes to consistently protecting the user from high electrical energy transients and impulses. When an impulse does overcome the insulation in the solenoid windings, the tester will no longer work, and the failure mechanism is not predictable. Electronic, electrical testers like the Fluke T+ and T+ PRO are built using protection components and circuitry that were specifically designed to safely withstand repeated encounters with the specified level of high-energy impulses and keep working.