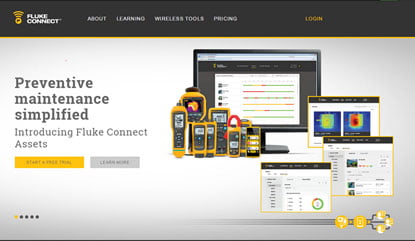

What if there was a way to automatically compile and organize all of the data collected by Fluke Connect test tools into a new kind of data-management software? Something designed specifically for maintenance managers? It would have to be seamless. No extra work, training, IT requests, or significant capital required.

That's Fluke Connect® Assets.

Fluke Connect Assets is a cloud-based wireless system of software and Fluke Connect enabled test tools that collects all of the measurement data taken by the wireless tools into an easy-to-use online database and dashboard. Fluke Connect makes saving maintenance data to relevant equipment logs as easy as a cell phone tap.

Having all of this data meaningfully aggregated and online gives maintenance managers a comprehensive view of their critical equipment — including baseline, historical, and current test tool measurement data, current status, and past inspection data. At a minimum, maintenance prioritization becomes much more efficient. At a maximum, the system enables maintenance managers to set up and sustain a preventive maintenance (PM) or condition-based maintenance (CBM) system easily with minimal investment.

Accurate equipment history

Fluke Connect Assets features the industry's only wireless one-step measurement transfer from more than 30 Fluke Connect wireless test tools. Technicians take a measurement with their test tool, use their phone to grab the data, and then click to save it to the database. The almost-automated process eliminates manual recording of measurements so maintenance managers can be more confident that the equipment history is accurate.

With Fluke Connect Assets, maintenance managers can:

- Get a complete historical overview of all assets on one screen. Fluke Connect Asset Health Dashboard aggregates status, measurements, and alarms over time in a quickly digestible, visual overview. Managers can compare all the measurement data (thermal, electrical, vibration, etc.) for each piece of equipment and drill down as needed to justify repair/replace decisions. The goal is to enable managers to quickly identify where they need to focus their resources as part of a routine preventive maintenance program.

- View a running news feed of equipment status. Fluke Connect Asset Status Dashboard provides continuous information on the status of equipment. The feed can be filtered by equipment status (extreme, serious, moderate, or slight) so managers can focus their attention to plan a course of action.

- Analyze multiple measurements in one place. The Fluke Connect Asset Analysis tab has data-driven graphics representing all the measurements collected on an asset. Managers can see trend graphics, review vibration spectra, and view thermal images side by side all in one place. By comparing the data from multiple measurements, managers can make better decisions on repairs and replacements.

- Realize a quick return on investment. Fluke Connect Assets is cloud-based (runs on external servers connected by the Internet) so it can be implemented without support from IT or capital expenditure outside of any test tools that may be needed. Fluke Cloud™ storage uses state-of-the-art electronic surveillance, multi-factor access control systems, built-in firewalls, encrypted data storage, and secure access specifically designed to protect data. Software is automatically updated and no support is required.

- Gain quick access to data with paper free, wireless one-step measurement transfer. Straight from the test tools into the database and dashboard. Reduces error and recaptures time spent searching for records.

- Receive trusted reporting from the field. Users can create accurate, traceable records that are easily accessed from anywhere. That data can quickly generate reports while the knowledge is still fresh — right at the point of measurement.

The Fluke Connect system streamlines maintenance tasks, eliminates manual data recording, and enables collaboration wherever workers are in the field - and now with Fluke Connect Assets aggregates that data into an easy to use management dashboard that enables maintenance managers to make informed repair/replace decisions on all the equipment in the plant.