Digital multimeters, volt meters, and electrical meters

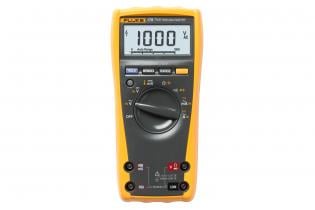

Fluke Digital Multimeters (DMMs) are on more tool belts, finding more problems, than any other test tools. Each industrial meter is tested to the extreme: drop, shock, humidity, you name it. Every Fluke Digital Multimeter gives you what you need: accurate measurements; consistent, reliable performance; attention to safety; and the strongest warranty available.

Find the right digital multimeters

Digital multimeter solutions

Save up to 38% on kits

Fluke 117 Electrician's Multimeter with Non-Contact Voltage

Work fast with integrated non-contact voltage detection.

Fluke 179 True-RMS Digital Multimeter

Industry-standard troubleshooting tester for electrical systems.

Fluke 115 Field Technicians Digital Multimeter

Ideal where reliability and dependability are required

Fluke 177 True-RMS Digital Multimeter

Measure twice as fast as other multimeters with Fluke 177 Digital Multimeters; digital display with...

Fluke 289 True-RMS Data Logging Multimeter

The Fluke 289 industrial logging multimeter allows you to log and zoom in on problems.

Fluke 28 II Rugged Digital Multimeter

Fluke 28 II rugged multimeter with IP 67 rating; tested to withstand a 3 m drop to operate in...

Fluke 116 Digital HVAC Multimeter

Specifically designed for HVAC professionals for temperature and microamp measurements, the Fluke...

Fluke 287 True-RMS Electronics Logging Multimeter

The Fluke 287 electronics multimeter allows you to log and zoom in on problems.

Fluke 114 Electrical Multimeter

Compact multimeter for electrical troubleshooting Easy one-hand operation with automatic AC/DC...

Fluke 233 Remote Display Digital Multimeter

The Fluke 233 with a removable display gives you ultimate flexibility in unusual measurement...

Fluke 83V Average Responding Industrial Multimeter

The Fluke 83V Industrial Multimeter delivers accurate voltage, current, frequency and capacitance...

Fluke 28 II Ex Intrinsically Safe True RMS Digital Multimeter

The Fluke 28 II Ex is the most rugged and reliable intrinsically safe digital multimeter in the...

Fluke 175 True-RMS Digital Multimeter

The Fluke 175 True RMS Digital Multimeter the baseline meter for troubleshooting and repair of...

Fluke 27 II Rugged Digital Multimeter

Fluke 27 II rugged multimeters with IP 67 rating; tested to withstand a 3 m drop to operate in...

Fluke 88V Deluxe Automotive Multimeter

Automotive measurements include pulse width, duty cycle, Min/Max/Avg recording

Fluke 77 IV Digital Multimeter

Fluke digital multimeters are designed to provide precision and accuracy!

Fluke 179/TPAK Combo Kit - Includes Meter and Magnetic Hanger

Hang Your Meter to Increase Ease-of-Use

Fluke PRV240FS Proving Unit: Test Voltage Indicators

Prove operation of FieldSense on T6 electrical testers

Fluke a283 FC True-RMS CAT III 1500V Wireless Current Clamp

The Fluke a283FC True-RMS CAT III 1500V Wireless Current Clamp simplifies troubleshooting without...

Fluke 87V MAX E2 Industrial Electrician Combo Kit

Combo Kit includes Fluke 87V MAX, alligator clips, test leads and probes and magnetic hanging strap.

Fluke 87V/E2 Industrial Electrician Combo Kit

Combo kit with the Fluke 87V Industrial Multimeter, heavy duty test leads, alligator clips and test...

Fluke 87V IMSK Industrial Multimeter Service Combo Kit

Combo kit includes Fluke 87V industrial multimeter, i400 AC current clamp and accessories.

Fluke 289 FlukeView® Forms Combo Kit

The Fluke 289 electronics multimeter allows you to log and zoom in on problems.

Fluke 287 FlukeView® Forms Combo Kit

The Fluke 287 electronics multimeter allows you to log and zoom in on problems.

Fluke 116/62 MAX+ Technician’s Combo Kit

Combine the power of Fluke's 116 HVAC Multimeter with a Fluke 62 MAX+ infrared thermometer for...

Fluke T5-1000 / PRV240 Proving Unit Kit

The FLUKE-T5-1000/PRV240 is a Voltage/Continuity/Current Tester and Proving Unit Kit. The Fluke...

Fluke 117 Multimeter and PRV240 Proving Unit Kit

Includes Electrician’s Multimeter with Non-Contact Voltage and Fluke PRV240 Proving Unit

Fluke 116/323 HVAC Combo Kit - Includes Multimeter and Clamp Meter

Combine the power of Fluke's 116 HVAC Multimeter with a Fluke 323 clamp meter for productive and...

Fluke 179/61 Industrial Multimeter and Infrared Thermometer Combo Kit

Created for industrial, HVAC, and facility maintenance.

Fluke 117/323 Electricians Combo Kit, Digital Multimeter and Clamp Meter

Versatile, rugged multimeter and general-purpose clamp meter.

What is a digital multimeter?

A digital multimeter (DMM) is an advanced electrical meter that combines multiple measurement functions into one unit. It can measure voltage, current, and resistance with high precision. These digital devices are particularly valued for their accuracy, as they convert analog signals into digital data, which is then displayed on an easy-to-read screen. This conversion allows for more precise readings compared to analog meters. Digital multimeters from renowned brands like Fluke are sought after for their durability, advanced features, and reliability in providing accurate measurements in various electrical and electronic work.

What does a digital meter measure?

A digital meter is a versatile instrument used in electrical and electronic work to measure several critical electrical parameters. Its primary function is measuring voltage (AC and DC), current (AC and DC), and resistance. Advanced digital meters can also measure capacitance, frequency, duty cycle, and temperature. Some models include additional features like diode testing and continuity checking, making them indispensable tools for various electrical diagnostic tasks.

What are the benefits of a digital multimeter?

The advantages of using a digital multimeter are numerous:

- They offer high accuracy in readings, making them reliable for precise measurements. The digital display significantly reduces reading errors, a common issue with analog meters.

- Their versatility allows users to measure different electrical parameters with a single device, enhancing convenience and efficiency. Digital multimeters are generally user-friendly, with features like auto-ranging, backlit displays for working in low-light conditions, and data hold functions.

- They are designed with safety in mind, offering features like overload protection, which is crucial for working in high-voltage or high-current environments.

What is a digital multimeter used for?

Digital multimeters are extensively used in various fields, from basic electrical repair and DIY projects to complex industrial applications. Electricians and technicians use them to troubleshoot and diagnose electrical circuit and component problems. In a household setting, they can be used to check the battery life, test electrical outlets, and identify wiring problems. In industrial settings, they are indispensable for ensuring the proper operation of electrical equipment, performing preventive maintenance, and ensuring compliance with electrical standards.

How does a digital multimeter work?

A digital multimeter works by measuring the electrical properties of a circuit and converting these measurements into a digital readout. When measuring voltage, for example, the multimeter detects the potential electrical difference between two points and displays this as a voltage reading. For current measurement, it measures the flow of electric charge, and for resistance, it measures how much an object resists the flow of electricity. The user selects the type of measurement via a dial or buttons on the meter, connects the probes to the test points, and the internal circuitry of the multimeter processes the readings, displaying them on a digital screen.

How do you read a digital multimeter?

Reading a digital multimeter involves interpreting the numeric value displayed on its digital screen. This display will indicate the magnitude of the measurement in the appropriate units, such as volts (V) for voltage, amperes (A) for current, and ohms (Ω) for resistance. Some digital multimeters also feature symbols or additional information on the screen to guide the user, such as indicating whether the measurement is in AC or DC for voltage. Understanding the selected function setting and range is crucial for accurately interpreting the readings.

How do you measure voltage with a digital multimeter?

Measuring voltage with a digital multimeter involves setting the multimeter to the correct voltage range and selecting between AC or DC voltage based on the measured source. The red probe is typically connected to the point of higher potential, and the black probe to the lower potential or ground. Once the probes are securely attached, the voltage reading will be displayed on the multimeter's screen. Selecting the correct voltage range is essential to avoid damaging the meter or getting inaccurate readings.

What is a digital voltmeter?

A digital voltmeter is a specific type designed exclusively to measure an electrical circuit's voltage. Unlike multimeters, digital voltmeters are dedicated solely to this task, providing a precise digital voltage readout. They are widely used in educational and professional settings where accurate voltage measurements are essential.

What does a digital voltmeter do?

A digital voltmeter measures the voltage difference between two points in an electrical circuit, displaying the value digitally. It operates by converting the analog signal of the voltage into a digital representation, allowing for precise and accurate readings. This device is crucial for applications that demand exact voltage readings, including the design of circuits, the examination of electrical devices, and the diagnosis of electrical issues.

What is a voltmeter used for?

Voltmeters are primarily used for measuring the voltage levels within electrical circuits. This measurement is crucial in various applications, including electrical troubleshooting, verifying the proper functioning of electrical devices and systems, and ensuring the safety of electrical installations. By measuring voltage, voltmeters help diagnose issues like voltage drops or overvoltages in circuits, which are critical for maintaining the functionality of electrical systems.

How does a voltage meter work?

A voltage meter, or voltmeter, measures the difference between two points in an electrical circuit. When connected across these points, it detects the voltage. It converts it into a readable format, either as a needle movement on an analog scale or as a numerical value on a digital display. The accuracy and resolution of the reading depend on the design and quality of the voltmeter.

What is the difference between a digital multimeter and a digital voltmeter?

The critical difference between a digital multimeter and a digital voltmeter lies in their range of functions. A digital multimeter is a multipurpose tool that measures voltage, current, resistance, and often additional parameters such as capacitance and frequency. On the other hand, a digital voltmeter is specialized for measuring voltage only. While a multimeter offers versatility for various electrical testing needs, a voltmeter provides focused functionality for accurate voltage measurement.

What are electric meters?

Electric meters, also known as electrical meters, are instruments used to measure various electrical quantities in circuits and electrical systems. These meters can measure voltage, current, power, energy, and other electrical parameters. They are essential in various applications, from household energy monitoring to industrial electrical system management, ensuring accurate measurement and monitoring of electrical usage and performance.

What are the types of electric meters?

Electric meters come in several types, each designed for specific measurement purposes. These include digital multimeters, which measure multiple electrical quantities; analog meters, known for their simplicity and durability; clamp meters, used for measuring current without direct contact; wattmeters, which measure power in a circuit; and energy meters, commonly used in homes and businesses to measure electricity consumption.

What are electric meters used for?

Electric meters are used for a wide array of purposes in both residential and industrial settings. They are critical for installing and maintaining electrical systems, troubleshooting electrical issues, and ensuring the safety and efficiency of electrical operations. In residential settings, electric meters, like energy meters, help in monitoring electricity usage for billing purposes. These meters are integral for system diagnostics, preventive maintenance, and energy management in industrial environments.

How to Check Voltage with an Electric Multimeter

Using a multimeter to measure voltage involves a few key steps: ensuring safety, setting the device correctly, and accurately interpreting the results. Before beginning, it's critical to ensure all safety protocols are followed, including turning off power to the circuit if necessary. The multimeter should be set to the appropriate voltage type - AC (alternating current) for household circuits or DC (direct current) for batteries and similar power sources.

Once the multimeter is configured correctly, it's a matter of connecting the test leads to the appropriate points in the circuit. The device then provides a digital or analog reading, depending on the model, indicating the circuit's voltage. This reading is crucial for diagnosing issues, ensuring the proper functioning of electrical devices, and verifying that circuits are correctly configured.

What is a digital meter?

A digital meter is an electronic device used to digitally measure and display electrical quantities. Unlike analog meters, which use a needle and dial, digital meters show readings on an LCD or LED screen, offering higher precision and easier readability. Digital meters encompass a range of devices, including digital multimeters, digital voltmeters, and digital current meters. They are widely used in various settings, from residential and commercial electrical systems to complex industrial machinery, due to their accuracy, versatility, and ease of use. The term' digital meter' often refers to meters that measure electrical properties like voltage, current, resistance, and sometimes other parameters such as capacitance, frequency, and temperature.

How does a digital current meter work?

A digital current meter measures the flow of electrical current in a circuit and displays the reading digitally. It detects the current flow through a conductor or a circuit and converts it into a digital signal. This conversion is typically done using a current transformer or shunt, translating the magnetic field or voltage drop. This is caused by the current flow into a measurable electrical signal. This signal is then processed by the meter's internal circuitry and displayed as a digital readout, usually in amperes (A). Digital current meters are commonly used in both AC and DC circuits. They are essential for tasks such as checking the current draw of an appliance and diagnosing electrical faults that ensure the safe operation of electrical systems.

What are the disadvantages of a digital meter?

While digital meters offer numerous advantages, there are some drawbacks to consider. One of the main disadvantages is their dependence on a power source, usually batteries, for operation. This means they can become non-functional if the power source is depleted or fails. Additionally, digital meters can be more sensitive to external factors such as temperature fluctuations or electromagnetic interference, potentially affecting their accuracy. The complexity of digital meters can also be a disadvantage, as it may require more technical knowledge to operate and interpret results than more straightforward analog meters. Furthermore, digital meters are often more expensive than their analog counterparts, which can be a limiting factor for some users. Finally, in extreme precision requirements, more than the resolution of a digital meter may be required, requiring more specialized equipment.